1. 个人简介

林忠财(LING TUNG CHAI),马来西亚华裔,必赢437官方网站教授,博士生导师。国家级高层次人才。曾在马来西亚、中国香港、英国和美国高校及研究院任职,长期专注于固废资源化利用与CO2技术等应用基础研究。主持负责国家基金委(包括外国资深学者)、科技部(包括高端外国专家引进计划)、省重点研发计划(“一带一路”专项)、香港创新及科技局科研项目等20余项。已在国际著名期刊《Nature Sustainability》等发表国际期刊论文180余篇(通讯125篇),WoS他引共计10,000余次,h-index为61,出版专著1部,参编专著9部,授权专利13项,作国内外学术会议大会、特邀报告30余次,连续多年入选中国高被引学者(土木工程领域),连续五年入选全球前2%顶尖科学家(职业生涯)。现为东盟工程与技术科学院Fellow、香港混凝土学会Fellow,任国际期刊ASCE《Journal of Materials in Civil Engineering》副主编及多个国内国际期刊编委。获美国国家科学研究委员会(NRC)Research Associateship Programs(Senior Level)Award以及国际材料与结构研究实验联合会(RILEM)授予的Robert L'Hermite奖章(中国高校首位,全球每年遴选一位)。

WoS Research ID: https://webofscience.clarivate.cn/wos/author/record/AAG-5617-2019

Scopus ID: https://www.scopus.com/authid/detail.uri?authorId=25225783400

个人主页: http://www.tcling.com

2. 教育背景

2005/07 – 2008/08:马来西亚理工大学,土木工程,博士学位

2003/07 – 2005/06:马来西亚理工大学,道路与交通,硕士学位

1999/07 – 2003/08:马来西亚理工大学,土木工程,学士学位

3. 科研与学术工作经历

2024/12 – 至今: 必赢437官方网站,必赢437官方网站,教授,博导

2016/02 – 2024/12:湖南大学,教授

2015/06 – 2016/01:美国联邦公路管理局,高级研究员

2014/06 – 2015/05:香港纳米及先进材料研发院,项目主管

2014/01 – 2014/06:香港理工大学技术与顾问有限公司,研究员

2012/03 – 2013/12:英国伯明翰大学,讲师

2009/06 – 2012/02:香港理工大学,博士后

4. 学术兼职

Fellow

2022 – 至今:东盟工程与技术科学院 (AAET)

2016 – 至今:香港混凝土学会 (HKCI)

资深会员

2016 – 至今:国际材料与结构研究实验联合会(RILEM)

专委会

2022 – 至今:RILEM TC 309-MCP用于建筑材料生产的加速矿物碳酸化专委会 课题负责人

2022 – 至今:RILEM TC UMW将粉末矿物“废料”升级再利用为水泥基材料专委会 委员

2017 – 2023:RILEM TC 279-WMR固废利用专委会 委员

2017 – 2024:RILEM TC 281-CCC碳化混凝土专委会 委员

2016 – 2020:RILEM TC 258-AAA混凝土碱骨料反应专委会 委员

2017 – 至今:美国混凝土协会(ACI) Committee 555废弃混凝土专委会 委员

学术委员会

2023 – 至今:中国硅酸盐学会固废分会碳矿化材料与技术学术委员会 主任

2024 – 至今:中国土木工程学会绿色建造与运维分会第一届理事会 理事

2021 – 至今:中国硅酸盐学会固废与生态材料分会第二届理事会建筑固废学术委员会 理事

2016 – 至今:美国混凝土协会(ACI)中国分会 理事

2016 – 至今:美国硅酸盐学会水泥分会会员

特刊主编

2022 - 2024:Case studies in Construction Materials

副主编

2020 – 至今:美国土木工程师协会 (ASCE) Journal of Materials in Civil Engineering

青年通讯专家

2022 – 至今:Engineering

2021 – 至今:湖南大学学报(自然科学版)

期刊编委

2022 – 至今:Waste Disposal & Sustainable Energy

2021 – 至今:Road Materials and Pavement Design

2019 – 至今:矿物治金与材料学报(英文版)

2017 – 至今:The Open Construction & Building Technology Journal

2016 – 至今:浙江大学学报:A卷(英文版)

2010 – 至今:Journal of Civil Engineering and Construction Technology

5. 研究方向

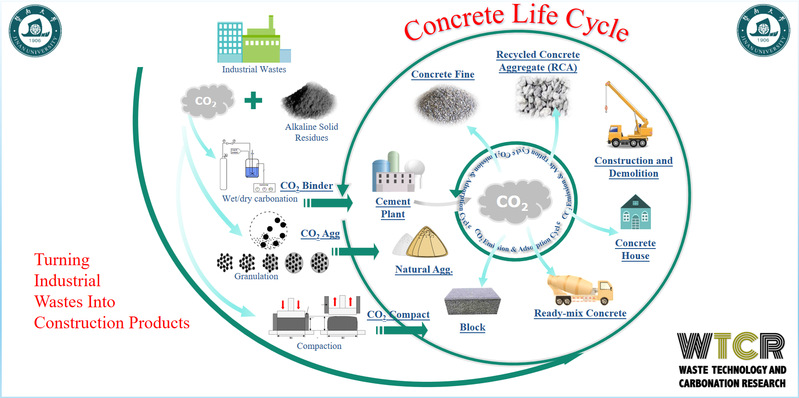

主要围绕固废资源化及碳矿化技术

1) 固废资源化利用

2) 碳化技术与计算模拟

3) 绿色建筑材料开发与应用

4) 碳核算与全生命周期评估

6. 国家级人才及科研项目

主持的项目

1) 国家基金委外国学者研究基金项目(52250710158), Waste Recycling and CO2 Sequestration for Sustainable Construction Materials

2) 国家基金委面上项目(52078202), 关于二氧化碳(CO2)养护对水泥基材料高温性能影响的基础研究

3) 国家外专局高端外国专家引进计划(G2021160018L), 碳化造粒技术对生活垃圾焚烧飞灰处理应用关键技术研究

4) 国家外专局外国青年人才计划(QN2021160002L), γ-C2S早期碳化机理研究, 2021-2022

5) 国家外专局外国青年学者研究基金项目(QNJ2021160001), Use of calcium-rich waste concrete and CO2 to produce carbonated slurry for enhancing cementitious materials

参与的项目

1) 国家自然科学基金重点项目(U1605242), 海洋环境下高性能再生混凝土材料制备和结构设计的基础理论研究,课题负责人,2017-2020

依托人 (Host Researcher)

1) 国家基金委外国青年学者研究基金项目(51950410584), Use of Calcium-rich Waste Concrete and CO2 to Produce Carbonated Slurry for Enhancing Cementitious Properties,2020.01-2021.12,Dr. Hamideh Mehdizadeh (团队外籍博士后)

2) 国家基金委外国青年学者研究基金项目(5181101350), Carbonation of Ready-mix Concrete by Direct Infusion of Carbonated Solution,2019.01-2020.12,Dr. Nicholas Lippiatt (团队外籍博士后)

3) 国家基金委外国青年学者研究基金项目(5171101225), Production of Artificial Aggregate from Concrete Wastes and CO2 Sequestration,2018.01-2019.12,Dr. Senthil Kumar (团队外籍博士后)

外国青年人才引进项目

1) 国家外国专家局及教育部—2021年外国青年人才引进项目(1项)

2) 国家外国专家局及教育部—2020年外国青年人才引进项目(1项)

3) 国家外国专家局及教育部—2019年外国青年人才引进项目(1项)

4) 中国科学技术交流中心—2018-2019年第二批国际杰青计划

5) 国家外国专家局及教育部—2018年外国青年人才引进项目(3项)

6) 国家外国专家局及教育部—2017年外国青年人才引进项目(2项)

7. 代表性论著(仅列举近三年通讯文章)

Orcid: https://orcid.org/0000-0002-8276-5212

Scopus: https://www.scopus.com/authid/detail.uri?authorId=25225783400

GoogleScholar: https://scholar.google.com/citations?user=gFgzLrYAAAAJ&hl=en

1) Song, Q.F., Guo, M.Z., Ling, T.C.* (2024). Optimization of BOFS high-gravity carbonation technology: Consideration of theoretical guidance for up-scaling applications, Journal of Cleaner Production, 469: 143214

2) Liu, Y.H., Mehdizadeh, H., Li, L.F., Ling, T.C.* (2024). Optimize the filler fineness to improve the rheological properties of calcined clay limestone cement and its revelation on hydration, Journal of Building Engineering, 98: 111397

3) Mehdizadeh, H., Ma, M.T., Ling, T.C.* (2024). A closed-loop recycling of wastewater derived from aqueous carbonation of basic oxygen furnace slag in cement paste production, Journal of Building Engineering, 98: 111004

4) Ren, P.F., Sun, K.K., Mehdizadeh, H., Ling, T.C.* (2024). A novel use of incineration bottom ash for H2 aeration in the production of artificial lightweight aggregates, Journal of Cleaner Production, 477: 143840

5) Ren, P.F., Wang, A., Mo, K.H., Ling, T.C.* (2024). Fast-hardening production of high-strength BOFS aggregates by high-temperature carbonation curing, ACS Sustainable Chemistry and Engineering, 12: 4c04437

6) Ren, P.F., Mehdizadeh, H., Ling, T.C.* (2024). Performance investigation of the artificial aggregate by integrally recycling incineration bottom ash and fly ash, Cement and Concrete Composites 152: 105678

7) Luo, S., Guo, M.Z., Ling, T.C.* (2024). Modification of early-age microstructure and enhanced mechanical properties of cement paste via injecting low-dose CO2 at fresh stage, Construction and Building Materials, 438: 137284

8) Wang, X.L., Guo, M.Z., Ling, T.C.* (2024). Production of a novel belite-ternesite cement with high CO2 reactivity using 100% municipal solid waste incineration (MSWI) residues, Resources Conservation and Recycling, 209: 107785

9) Zhang, Y.M., Jiang, Y., Ling, T.C.* (2024). Use of CO2 as a controlled foam stabilizer to enhance pore structure and properties of foamed concrete. Cement and Concrete Composites, 145: 105356.

10) Song, Q.F., Guo M.Z., Ling, T.C.* (2024). Synthesis of high-purity and stable vaterite via leaching-carbonation of basic oxygen furnace slag, ACS Sustainable Chemistry and Engineering, 12: 4081-4091

11) Wei, J.X., Xiao, Y.J., Ling, T.C.*(2024). Enchantment of architectural luminescent-glass mortar (ALM) properties with encapsulation of white-color powder. Materials Today Communications, 38: 108296.

12) Yu, H., Tang, C.X., Mehdizadeh, H., Guo, M.Z., Ling, T.C.* (2024). Effects of early hydration of alite and belite phases on subsequent accelerated carbonation. Construction and Building Materials, 411: 134675.

13) Yu, H., Guo, M.Z., Ling, T.C.* (2024). Influence of gas impurities (SO2 and NOX) in flue gas on the carbonation and hydration of cement compacts. Journal of Building Engineering, 82: 108333.

14) Li, X.D., Mehdizadeh, H., Ling, T.C.* (2023). Environmental, economic and engineering performances of aqueous carbonated steel slag powders as alternative material in cement pastes: Influence of particle size. Science of the Total Environment, 903: 166210.

15) Luo, S., Guo, M.Z., F.P., Pham B.T., Liu, H.B., Ling, T.C.* (2023). Role of interaction between molding pressure and CO2 pressure in carbonating cement block. Journal of Building Engineering, 78: 107579.

16) Song, Q.F., Deng, S.X., Ling, T.C.* (2023). Study on the crushing strength improvement of artificial aggregates made with 100% solid wastes using polyvinyl alcohol solution. Construction and Building Materials, 400: 132576.

17) Lei, X.Y., Yu, H., Feng, P., Ling, T.C.* (2023). Flue gas carbonation curing of steel slag blocks: Effects of residual heat and water vapor. Construction and Building Materials, 348: 131330.

18) Mehdizadeh, H., Wu, Y.Q., Mo, K.H., Ling, T.C.* (2023). Evaluation of carbonation conversion of recycled concrete fines using high-temperature CO2: Reaction kinetics and statistical method for parameters optimization. Journal of Environmental Chemical Engineering, 11(3): 109796.

19) Wang, M.L., Luo, S., Pham, B.T., Ling, T.C.* (2023). Effect of CO2-mixing dose and prolonged mixing time on fresh and hardened properties of cement pastes. Journal of Zhejiang University-Science A, 24(10): 886-897.

20) Yu, Z., Meng, Y.Z., Mo, K.H., Liu, H.B., Ling, T.C.* (2023). Influences of w/c and CO2 curing duration on the high temperature properties of cement pastes. Journal of Building Engineering, 69: 106293.

21) Song, Q.F., Guo, M.Z.*, Gu, Y., Ling, T.C.* (2023). CO2 curing of SCMs blended cement blocks subject to elevated temperatures. Construction and Building Materials, 374: 130907.

22) Li., Y.S., Mehdizadeh, H., Mo, K.H., Ling, T.C.* (2023). Co-utilization of aqueous carbonated basic oxygen furnace slag (BOFS) and carbonated filtrate in cement pastes considering reaction duration effect. Cement and Concrete Composites, 138: 104988.

23) Wei, J.X., Mo, K.H., Ling, T.C.* (2023). Roles of subsequent curing on the pH evolution and further hydration for CO2 cured cement pastes. Journal of Building Engineering, 64: 105701.

24) Mehdizadeh, H., Mo, K.H., Ling, T.C.* (2023). CO2-fixing and recovery of high-purity vaterite CaCO3 from recycled concrete fines. Resources, Conservation & Recycling, 188: 106695.

25) Li, L.F., Shao, X., Ling, T.C.* (2023). Life cycle assessment of coal gangue composite cements: From sole OPC towards low-carbon quaternary binder. Journal of Cleaner Production, 414: 137674.

26) Zhang, L.J., Mo, K.H.*, Tan, T.H., Yap, S.P., Lee, F.W., Ling, T.C.* (2023). Synthesis and characterization of fiber-reinforced lightweight foamed phosphogypsum-based composite. Construction and Building Materials, 394: 132244.

27) Liu, Y.X., Zhang, Y.L., Li, L.F., Ling, T.C.* (2023). The impact of limestone/metakaolin ratio on the performance and hydration of ternary blended cement. ASCE Journal of Materials in Civil Engineering, 35(4): 04023027.

28) Shao, X., Li, L.F., Ling, T.C.* (2023). Comparative Life cycle assessment of fast-curing methods for dry-mix and wet-mix cement pastes. ASCE Journal of Materials in Civil Engineering, 35(8): 04023231.

29) 王晓丽, 林忠财* (2022). 固废基低钙固碳水泥熟料组成设计及烧成过程. 建筑材料学报, 25(11): 1115–1120.

30) Luo, S., Guo, M.Z., Ling, T.C.* (2022). Mechanical and microstructural performances of fly ash blended cement pastes with mixing CO2 during fresh stage. Construction and Building Materials, 358: 129444.

31) Shao, X., Li, L.F., Ling, T.C.* (2022). Comparative life cycle assessment of fast-curing methods for dry-mix and wet-mix cement pastes. ASCE Journal of Materials in Civil Engineering, 35: 13979.

32) Shao, X., Mehdizadeh, Li, L.F., Ling, T.C.* (2022). Life cycle assessment of upcycling waste slag via CO2 pre-treatment: Comparative study of carbonation routes. Journal of Cleaner Production, 378: 134115.

33) Liu, Y., Ren, R.F., Garcia-Troncoso, N., Mo, K.H., Ling, T.C.* (2022). Roles of enhanced ITZ in improving the mechanical properties of concrete prepared with different types of recycled aggregates. Journal of Building Engineering, 60: 105197.

34) Wang, A., Ren, P.F., Zeng, Q., Ling, T.C.* (2022). Performance investigation and optimization of the granulation-CO2 concentration for the production of high-strength BOFS aggregates. Journal of CO2 Utilization, 64: 102160.

35) Mehdizadeh, H., Shao, X., Mo, K.H., Ling, T.C.* (2022). Enhancement of early age cementitious properties of yellow phosphorus slag via CO2 aqueous carbonation. Cement and Concrete Composites, 133: 104702.

36) Wang, X.L., Guo, M.Z., Ling, T.C.* (2022). Review on CO2 curing of non-hydraulic calcium silicates cements: Mechanism, carbonation and performance. Cement and Concrete Composites, 133: 104641.

37) Song, Q.F., Guo, M.Z.*, Ling, T.C.* (2022). A review of elevated-temperature properties of alternative binders: Supplementary cementitious materials and alkali-activated materials. Construction and Building Materials, 341: 127894.

38) Kaliyavaradhan, S.K., Li, L.F., Ling, T.C.* (2022). Response surface methodology for the optimization of CO2 uptake using waste concrete powder. Construction and Building Materials, 340: 127758.

39) Wu, Y.Q., Mehdizadeh, H., Mo, K.H., Ling, T.C.* (2022). High-temperature CO2 for accelerating the carbonation of recycled concrete fines. Journal of Building Engineering, 52: 104526.

40) Tiong, M., Li, X.M., Mo, K.H., Ling, T.C.* (2022). Effects of moulding pressure and w/c induced pore water saturation on the CO2 curing efficiency of dry-mix cement blocks. Construction and Building Materials, 335: 127509.

41) Deng, S.X., Ren, P.F., Jiang, Y., Shao, X., Ling, T.C.* (2022). Use of CO2-active BOFS binder in the production of artificial aggregates with waste concrete powder. Resources, Conservation & Recycling, 182: 106332.

42) Mehdizadeh, H., Cheng, X.F., Mo, K.H., Ling, T.C.* (2022). Upcycling of waste hydrated cement paste containing high-volume supplementary cementitious materials via CO2 pre-treatment. Journal of Building Engineering, 52: 104396.

43) Wang, Y.T., Mo, K.H., Du, H.J., Ling, T.C.* (2022). Effects of CO2 curing treatment on alkali-silica reaction of mortars containing glass aggregate. Construction and Building Materials, 323: 126637.

44) Chen, R.M., Mo, K.H., Ling, T.C.* (2022). Offsetting strength loss in concrete via ITZ enhancement: From the perspective of utilizing new alternative aggregate. Cement and Concrete Composites, 127: 104385.

45) Li, L.F., Ling, T.C.*, Zhong, X.Z. (2022). Effects of accelerated carbonation and high temperatures exposure on the properties of EAFS and BOFS pressed blocks. Journal of Building Engineering, 45: 103504.

46) Ren, P.F., Ling, T.C.*, Mo, K.H. (2022). CO2 pretreatment of municipal solid waste incineration fly ash and its feasible use as supplementary cementitious material. Journal of Hazardous Materials, 424(Part B): 127457.

47) Li, L.F., Ling, T.C.*, Pan, S.-Y. (2022). Environmental benefit assessment of steel slag utilization and carbonation: A systematic review. Science of the Total Environment, 806: 150280.

48) Liu, Y.X., Zhang, Y.L., Li, L.F., Ling, T.C.* (2022). The impact of limestone/metakaolin ratio on the performance and hydration of ternary blended cement. ASCE Journal of Materials in Civil Engineering, 35(4): 0004685.

49) Wang, X.L., Guo, M.Z., Yue, G.B., Li, Q.Y., Ling, T.C.* (2022). Synthesis of high belite sulfoaluminate cement with high volume of mixed solid wastes. Cement and Concrete Research, 158: 106845.

50) Zhang, Y.L., Liu, Y.X., Li, L.F., Ling, T.C.* (2022). Influence of kaolinite content in coal-series metakaolin and soft metakaolin on the performance of cement blends with and without limestone. Materials and Structures, 55:115.

51) Li, L.F., Zhang, Y.L., Liu, Y.X., Ling, T.C.* (2022). Upcycling coal- and soft-series metakaolin in blended cement with limestone. Construction and Building Materials, 327: 126965.

52) Zhang, L.J., Mo, K.H.*, Yap, S.P., Gencel, O., Ling, T.C.* (2022). Effect of fibers addition on mechanical properties of eco-friendly phosphogypsum-based composite at high temperatures. Journal of Building Engineering, 61: 105247.

53) Xiao, Y.J., Pham, B.T., Guo, M.-Z., Ling, T.C.* (2022). Influence of luminescent powder type and characteristic on the glow light performance of architectural glass mortar. Journal of Building Engineering, 58: 105021.

54) Zhang, L.J., Mo, K.H.*, Yap, S.P., Gencel, O., Ling, T.C.* (2022). Mechanical strength, water resistance and drying shrinkage of lightweight hemihydrate phosphogypsum-cement composite with ground granulated blast furnace slag and recycled waste glass. Construction and Building Materials, 345: 128232.

55) Xiao, Y.J., Pham, B.T., Guo, M.-Z., Ling, T.C.* (2022). Use of luminescent-glass aggregates for the production of decorative architectural mortar. Journal of Building Engineering, 50: 104233.

56) Kaliyavaradhan, S.K., Ling, T.C.*, Guo, M.-Z. (2022). Upcycling of wastes for sustainable controlled low-strength material: A review on strength and excavatability. Environmental Science and Pollution Research, 29(12): 16799-16816.

57) Xiao, Y.J., Tiong, M., Mo, K.H., Guo, M.-Z., Ling, T.C.* (2022). Recycling Bayer and sintering red muds in brick production: A review. Journal of Zhejiang University-SCIENCE A, 23(5): 335-57.

58) Radwan, M.K.H., Mo, K.H.*, Onn, C.C., Ng, C.G., Ling, T.C.* (2022). Waste press mud in enhancing the performance of glass powder blended cement. Construction and Building Materials, 313: 125469.

8. 专利

1) 一种利用二氧化碳改善再生混凝土性能的方法(中国发明专利)

2) 一种利用二氧化碳制备耐高温混凝土砌块的方法(中国发明专利)

3) 一种绿色节能的人造轻质骨料及其制备方法(中国发明专利)

4) 一种增强二氧化碳养护效果的高强度全钢渣砌块及其制备方法(中国发明专利)

5) 一种利用废弃玻璃生产可即时拆模地面砖的方法(中国发明专利)

6) 一种超重力碳化钢渣微粉的处理装置(中国实用新型)

7) 一种利用烟气及其余热规模化处理水泥基材料的碳化系统(中国实用新型)

8) 一种二氧化碳预拌水泥基复合材料的密封搅拌装置(中国实用新型)

9) 一种二氧化碳预拌水泥基复合材料的搅拌装置(中国实用新型)

10) Synthetic Aggregate from Waste Materials(美国专利)

11) Multi-Layer Fabric Reinforced Cementitious Matrix and Application Method Thereof(美国专利)

12) Rubberized Concrete Paving Blocks(马来西亚专利)

13) Highway Accelerated Loading Instrument(马来西亚专利)

9. 科研团队

自2016年起培养8位初级和高级研究员(1位交流学者、7位博士后研究员)、40余位博士、硕士研究生(其中多位分别和Kim Hung Mo教授(马来亚大学)和潘智生教授(香港理工大学)联合培养)。2024年,进一步拓展合作,与比利时根特大学(Nele De Belie教授)、东京大学(Ippei Maruyama教授)开展博士生联合培养及学生交换项目,为人才培养注入新活力。

研究团队详细介绍见网页https://www.tcling.com/及微信公众号(WTCR绿色建材)

欢迎土木、材料、化工、环境、建模等相关背景的青年才俊加入课题组,从事硕士、博士、博士后研究及相关教学科研工作。

联系方式:tungchailing@jnu.edu.cn,必赢437官方网站501-3办公室